top of page

3D printer

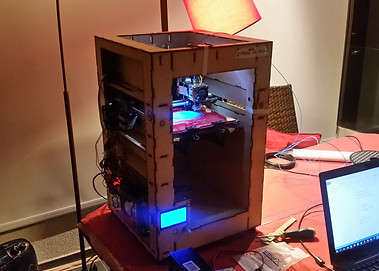

Design and construction of a 3D FDM printer called "Prisma UNO". It has a printing volume of 180x180x200mm, double extruder and its housing allows to house the filaments inside to provide ease of transport and compact appearance. It is capable of printing with traditional PLA, PVA and semi-flexible filaments.

The objective was to create a machine that is easy to replicate thanks to the use of 3D printed parts and standardized parts, as well as Open-Source software and an open housing that allows easy access to the printing area from the front.

>> See documentation on GitHub <<

This project began with the construction of a first prototype made of MDF, which was used to study the behavior of all the components and the structure. Very important information was obtained regarding the ergonomics of the printer, that is, the interaction with the user, as well as technical aspects related to the repair and maintenance of components and safety against possible failures.

In addition, it was used to print the parts of its improved version "Prisma UNO".

The firmware used is Marlin and the hardware is the traditional RAMPS v1.0. Some functionalities have been activated such as the detection of filament in the main extruder, the semi-automatic change of filament in both extruders (discharge, loading and / or change) and activation of cooling fans by temperature threshold.

Thanks to the blower head, some geometries can be printed without the need for supports. For more intricate shapes, the second extruder can be used to generate PVA support, which is soluble in water. Thus, shapes can be printed that with another process would not be possible to manufacture.

The minimum layer height that can be achieved with this printer is 0.1mm for traditional PLA filaments, reaching up to 0.3mm for fast, low-quality prints, competing with similar-end commercial printers.

bottom of page